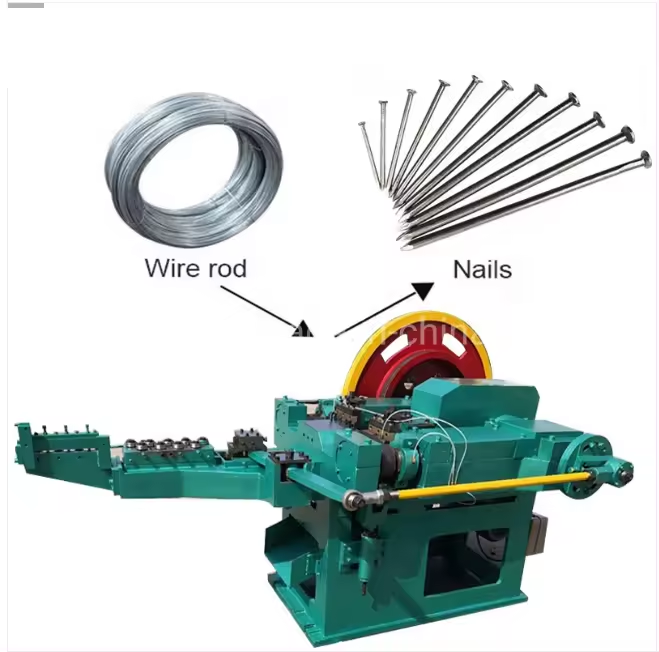

Wire nail making machine

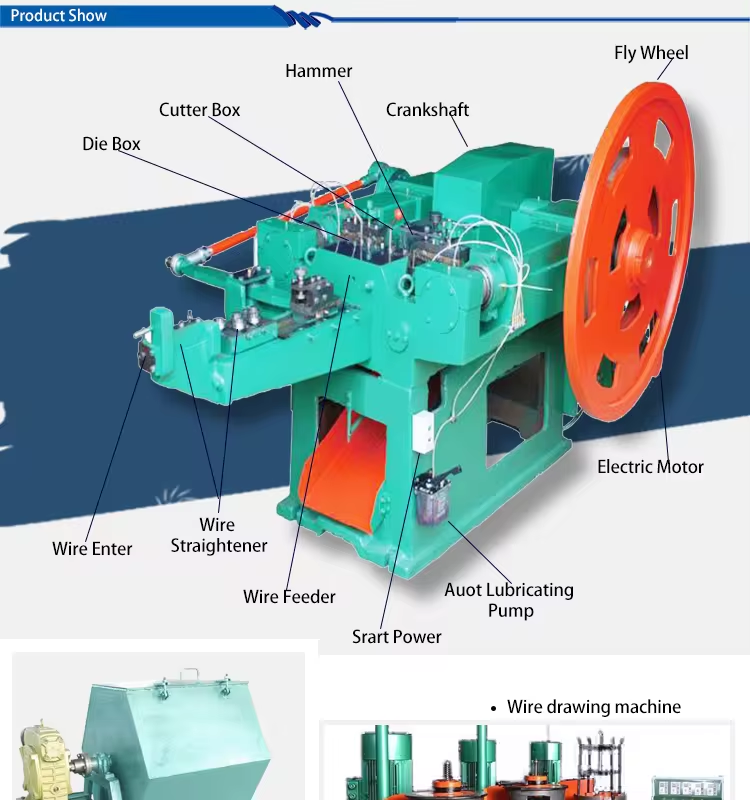

Nail making machine is a machine used for manufacturing nails. It typically consists of a curved nail feeder, a cutter, and a nail forming section. During the production process of nails, steel wire is fed through the feeder, cut by the cutter, and then bent into a specific shape at the forming section, ultimately resulting in a finished nail.

Description

Wire Nail Making Process:

1. Wire Straightening: put the wire coil on pay-off rack and input wire to traightening device for straightening.

2. Wire Feeding: The feeding box will grip and feed the steel wire continuously.

3. Nail head Forming: When the steel wire is clamped by the gripping mechanism, the punch system will punch the wire to form the

nail head.

4. Nail Tip Cutting: After the extrusion is completed, the cutting mechanism cuts the wire, and an emergency return mechanism can

be used.

5. Final Step: The gripping die open, the nail is dropped down and the next nail will be made continuously.

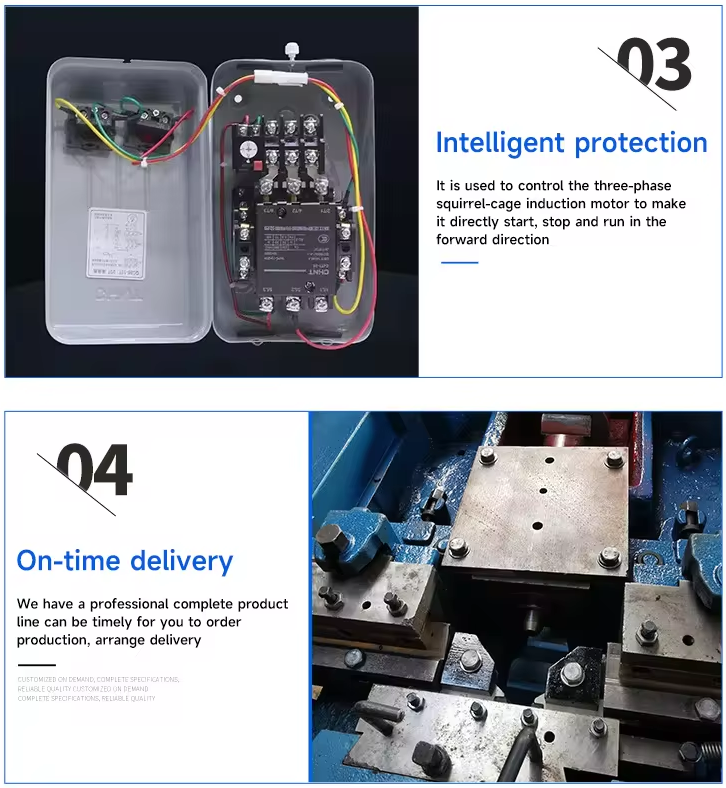

Machine advantages:

* Can make a wide range of wire nails according to different models; * fully automatic and uses Taiwan nail-making technology in the nail production process, this type is the most mature design in the world yet

* low running cost

* cheap spare parts price

* Low power consumption as with just 4 kilowatts of power.

* Simple construction and Easy on nail adjustment: ONLY 10 minutes To change the nail diameter and change the nail mold. ONLY 5 minutes To adjust the nail length, nothing needs to be changed.

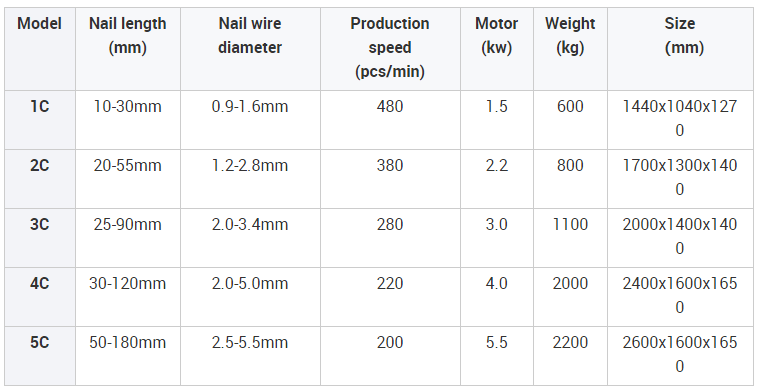

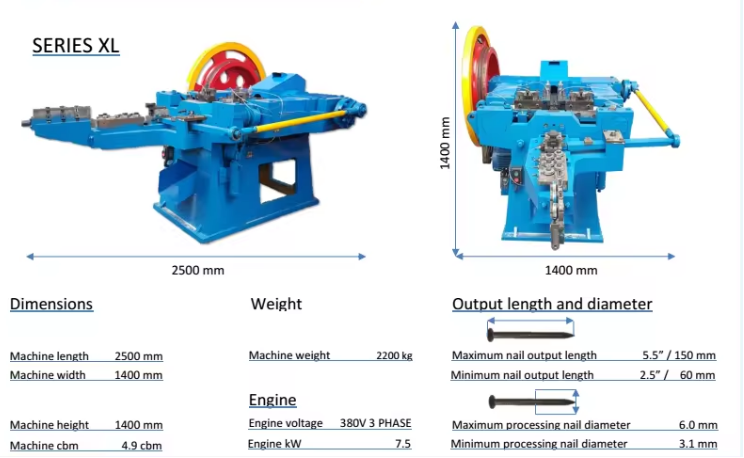

Parameter