Hydraulic breaker hammer

Hydraulic breaker hammer. Hydraulic breaker’s power source is excavators, loaders, or pumping stations’ pressure. It can break stones and rocks more effectively in engineering construction. The selection of the hydraulic breaker principle is according to the operating environment and excavator type.

Description

Product Features:

1.High temperature exercise technology ensures its wear resistance, durability, and high economic benefits.

2.The material used for the hammer shell and splint is wear-resistant, manganese steel material, to ensure that it will not crack.We use high-precision product matching, which fully guarantees the hammer’s striking strength.and each one is heat-treated to prevent each bolt from being elongated and deformed.

Mine Mining: mining, secondary crushing, grid crushing.

Metallurgy: ladle, slag cleaning, furnace dismantling, equipment foundation removal.

Highways: highway repairs, cement pavement broken, foundation excavation.

Railway: mountain breaking, tunnel excavation, road and bridge demolition, roadbed consolidation.

Building: eliminate demolition and broken reinforced concrete.

Ship repair: hull removal of clams and rust.

Others: ice breaking, soil breaking, sand vibration.

Technical parameters:

| Description | Operating Weight | Required Oil Flow | Impact Rate | Working Pressure | Rod Diameter | Applicable Carrier |

| Unit | KG | L/min | bmp | Kg/cm² | mm | ton |

| HL53 | 152 | 25-50 | 550-1000 | 90-120 | 53 | 2.5-4.5 |

| HL68 | 320 | 40-70 | 500-800 | 100-140 | 68 | 4-7 |

| HL75 | 400 | 50-90 | 450-800 | 120-150 | 75 | 6-9 |

| HL100 | 820 | 80-120 | 350-700 | 160-180 | 100 | 11-16 |

| HL135 | 1720 | 100-150 | 350-600 | 180-210 | 135 | 18-21 |

| HL140 | 1720 | 130-170 | 350-500 | 190-220 | 140 | 20-26 |

| HL150 | 2230 | 150-210 | 300-450 | 210-230 | 150 | 25-30 |

| HL155 | 2780 | 170-220 | 300-450 | 220-240 | 155 | 28-35 |

| HL165 | 3350 | 200-260 | 250-400 | 230-250 | 165 | 30-40 |

| HL175 | 3850 | 210-260 | 250-350 | 240-260 | 175 | 40-55 |

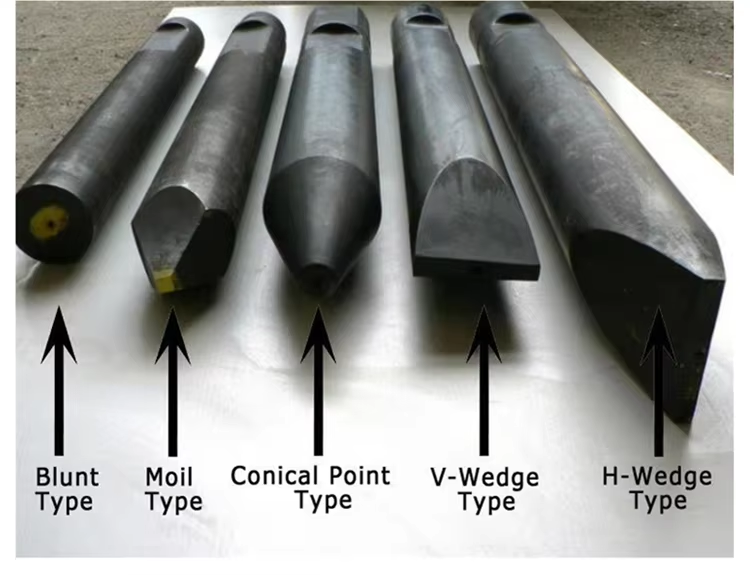

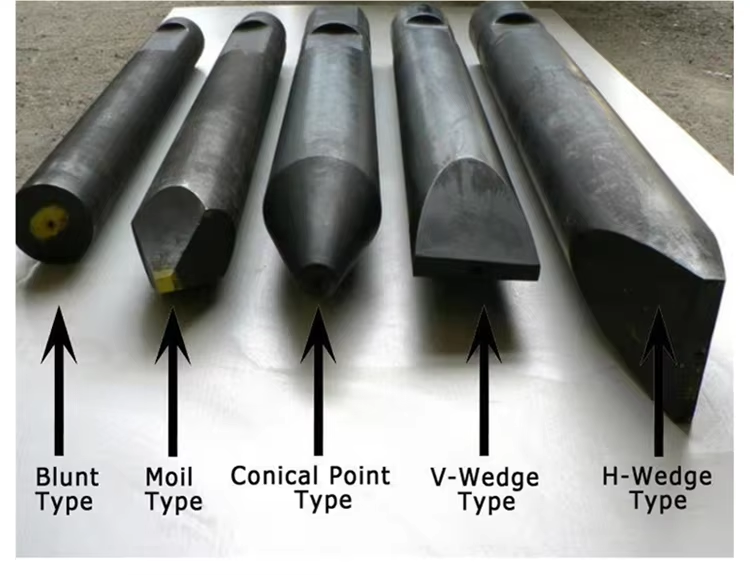

Pictures: