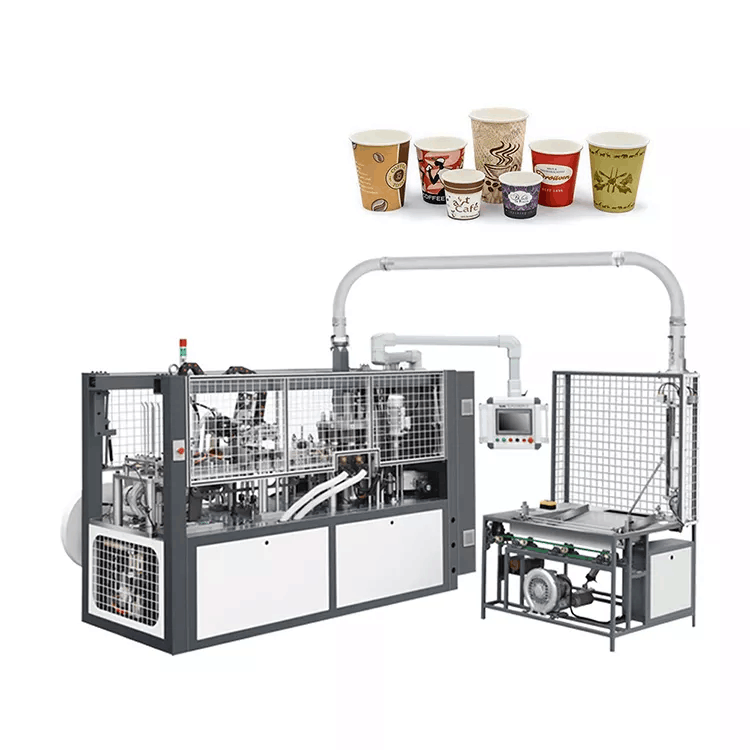

High speed paper cup making machine

Paper cup making machine is a fully automatic paper cup forming machine that can produce paper cups of different sizes through a series of continuous processes, including automatic paper feeding for more than 2 times, paper anti retreat device (ensuring accurate positioning), ultrasonic welding, magic hand transfer paper fan, silicone oil lubrication, bottom punching, bottom folding, bottom preheating, bottom embossing, and cup output. After comprehensive technological improvements, the stability of the machines developed by our company has been improved.

Description

Advantage:

The working principle of our paper cup machine is that a main motor drives the whole machine to work, which realizes the perfect integration of gear and cam structure. Now the machine uses a single aluminum plate to replace the previous three plate machine, which greatly reduces the machine failure rate and reduces the training time for the operator. 3- 16oz single and double coated paper cups can be customized according to customer requirements. It is a fully automatic paper cup forming equipment, through multi-row automatic paper feeding, paper anti-return device (to ensure accurate positioning), ultrasonic or copper strip welding, mechanical hand paper tube transfer, oil injection, bottom punching, bottom folding, preheating, and rolling Continuous processes such as flower and cup unloading can stably produce paper cups of various specifications.

Technical Parameters:

| Production speed | 120-150pcs/min |

| Voltage | 380V/50hz three phase |

| Machine package size | 2800x1400x1800mm ( L*W*H) |

| Material requirements | Single or double coated paper can be used |

| Power | 7.5kw |

| Weight | 2300Kg |

| Corresponding to the paper cup size | 3- 16oz |

| Paper thickness requirements | 150-350g/㎡ ; ±20g/㎡ |

| Gas supply requirements | 0.6-0.8mpa;0.4m³/min |

| The cup body sticks in | Copper bar |

| Bottom rolling flowers | Blowing heating / nest heating |

| Molds can be customized according to customer requirements

|

|