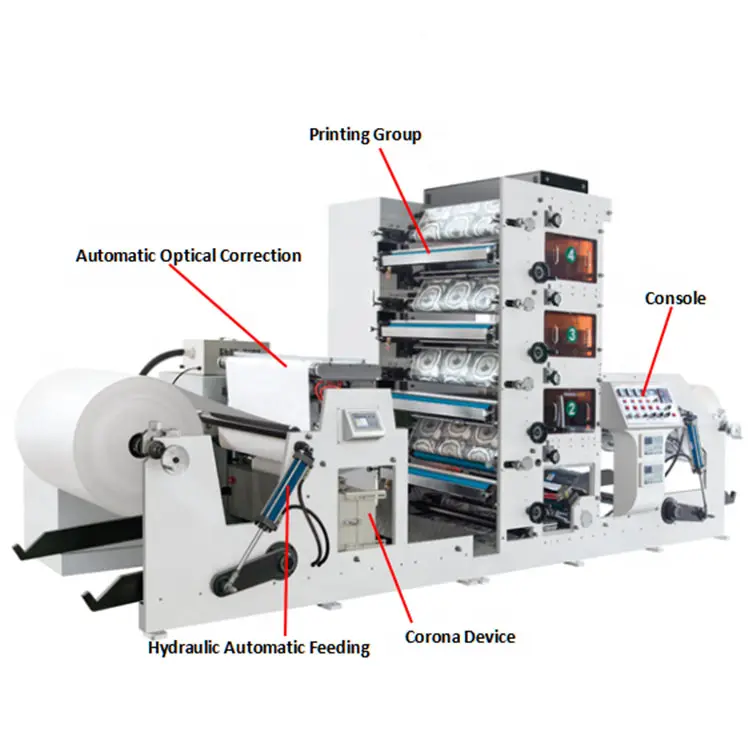

Flexo printing machine

Flexo printing machine is a spectacular blend of letterpress and rotogravure printing, employing relief plates made up of flexible rubber or photo-polymer plates. The machine can finish material-feeding,printing, varnish, drying, laminating, rewinding and die-cutting in one process.

Description

Main Feature

- Adopt the ceramic anilox cylinder to transfer the ink.

- Each printing unit adopts 360 .plate-adjustment.

- Three die-cutting stations,the first and second die-cutting station can do double sides working,the third die-cutting station can be used of sheeter.

- Computerized web-guiding system is installed in the front of printing unit,it ensures the material always in the right position.

- After sheeting in the third die-cutting station,conveyor belt can output the products orderly.(option)

- Unwinding and rewinding tension are auto-controlled by magnetic powder,two rewinders is possible in this machine.

- Video inspecting system is an option,it can watch the printing quality when in high speed.

- The ink rolleres will be separated from the printing roller,and keep running when the machine stops.

- Main machine inverter is imported.

- Manual/automatic pressure adjustment system: be more convenient to operate and reduce more working intensity.

Parameter

| Item | Parameters and functions | HL850 |

| 1 | Maximum unwinding diameter | 1000mm |

| 2 | Maximum winding diameter | 1000mm |

| 3 | print length | 181-450mm |

| 4 | Maximum paper width | 860mm |

| 5 | Maximum printing width | 850mm |

| 6 | Registration accuracy | ±0.12mm |

| 7 | Gear Specifications | 1/8CP, pitch is 3.175 |

| 8 | power demand | 380V 3PH 50HZ |

| 9 | machine design speed | 0-100m/min |

| 11 | Plate thickness | 1.7mm |

| 12 | Plate Tape Thickness | 0.38mm |

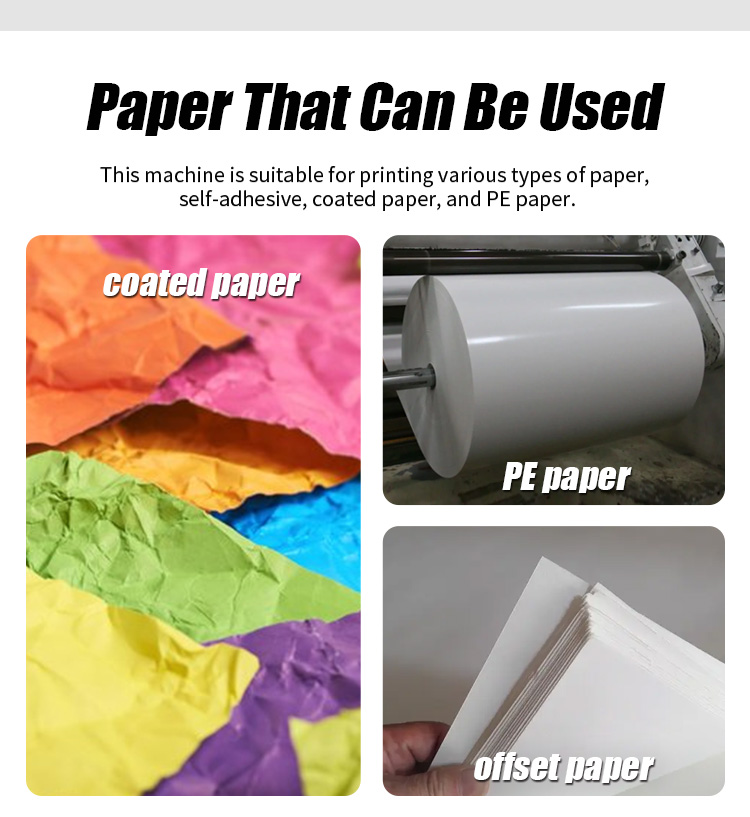

| 13 | printing material | 30-300 sheets |