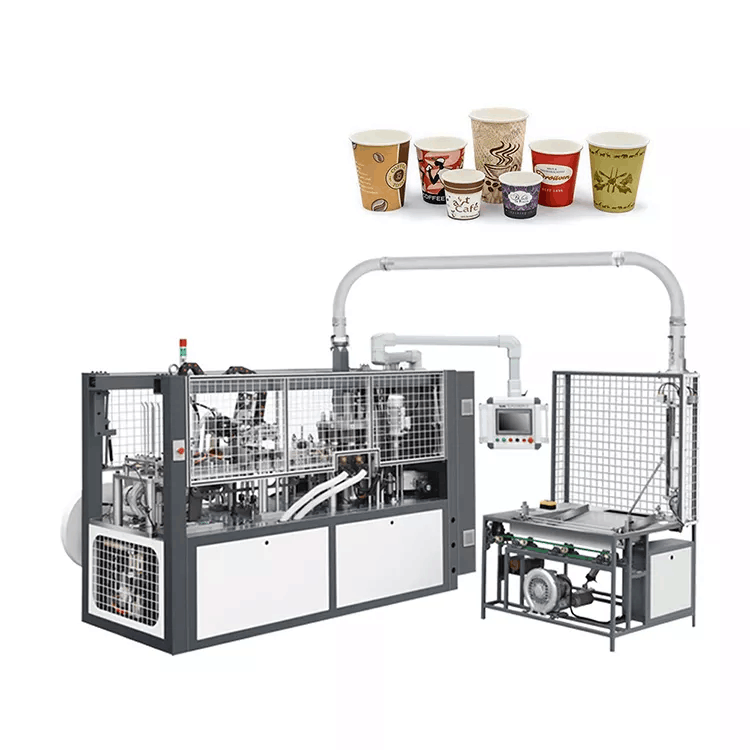

Automatic paper bag making machine

Paper bag making machine is used for roll primary color paper or printing roll paper such as kraft paper. Paper rolls such as food paper are completed by this machine at one time. Automatic center gluing, raw material into tube, cut to length, bottom indentation, bottom folding. Glue on the bottom and shape the bottom of the bag. Finished bag finishing is completed at one time. This machine is more convenient to operate, more efficient and more stable. It is an environmentally friendly paper bag machine equipment that produces various paper bags, snack food bags, bread bags, dried fruit bags, etc.

Description

Feature

- Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

- Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

- Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

- The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

- The raw material correction adopts servo motor to reduce the adjustment time of paper roll alignment.

Parameter

| Cutting Length | 270-530mm |

| Paper Bag Width | 120-350mm |

| Bottom width | 60-150mm |

| Paper bag thickness | 60-150g/㎡ |

| Mechanical speed | 30-220pcs/min |

| Paper bag speed | 30-180pcs/min |

| Paper roll width | 380-1050mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 15kw |

| The whole machine pressure | 0.5MPa-0.8MPa |

| Total Weight | 8500kg |

| Overall size | 10000*3700*2200mm |